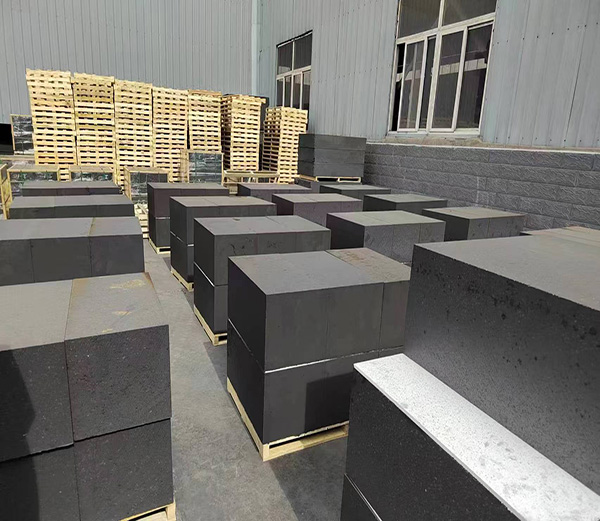

Product Overview/产品概述:

Carbon bricks are a kind of carbon refractory material made of coke, anthracite or graphite and tar as raw materials, which are mixed, formed and burned to 1450℃ in a reducing flame. The mass fraction of carbon is 88% to 90%. It can resist the corrosion of molten metal and various slags, but is easy to oxidize. It is used to build the bottom and belly of blast furnace.

Product Introduction/产品介绍:

1. It has extremely high refractoriness and does not melt or soften. It volatilizes only at very high temperatures (>3000℃). But this temperature cannot be reached in a blast furnace.

2. It has high compressive strength. Its compressive strength can reach 250-500kg/cm2, which is similar to clay bricks. But the compressive strength of clay bricks can reach up to 1000kg/cm2.

3. Its load softening point is much higher than that of clay bricks. The load softening temperature of general clay bricks is 1400℃, while the load softening temperature of carbon bricks does not exist (that is, the softening point is extremely high), but it must be pointed out that this is only for high-quality carbon bricks with low ash content.

4. It has good slag resistance. Except for slag with high FeO content, any slag cannot play a corrosive role.

5. It has high wear resistance, and its wear resistance is not inferior to that of clay bricks.

6. It is not wetted by iron and slag (iron slag cannot stick to carbon bricks), so there is less chance of nodules and less chance of damage due to interaction with iron and slag.

7. Small expansion coefficient. It will not produce cracks even if it is quenched at high temperature. This is a very necessary property for some parts that are easy to be damaged due to cracks (such as the furnace bottom), so the furnace bottom bricks are mostly made of carbon bricks.

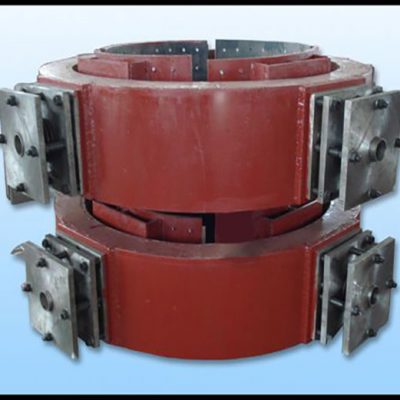

8. The thermal conductivity is much higher than that of clay bricks, especially graphite bricks. But its effect can be beneficial or harmful. Large heat loss is a negative effect, but it is beneficial to form slag skin in the lower part. When the lower part of the blast furnace is built with carbon bricks, cooling water is not required, and only air is used for natural cooling. Even some smaller blast furnace hearths do not need cooling at all. But generally, cooling water tanks are still used, because sometimes the quality of carbon bricks is not good and the hearth is easy to be damaged. If there is no cooling water tank, iron slag leakage accidents will occur. At the same time, installing cooling water tanks is not very troublesome. Therefore, cooling water tanks are still used when using carbon bricks.