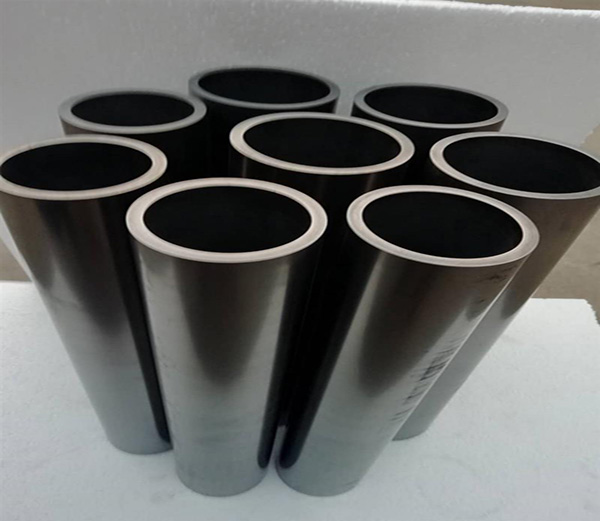

Product Overview/产品概述:

Graphite crucible, also known as copper melting bag, copper melting, etc., refers to a type of crucible made of graphite, clay, silica and wax stone. Graphite crucible is mainly used to smelt non-ferrous metals and their alloys such as copper, brass, gold, silver, zinc and lead.

Product Introduction/产品介绍:

Graphite crucibles are made of natural flake graphite as the main raw material and plastic refractory clay or carbon as a binder. They are characterized by high temperature resistance, strong thermal conductivity, good corrosion resistance, and long service life. During high-temperature use, the thermal expansion coefficient is small, and it has certain strain resistance to rapid cooling and rapid heating. It has strong corrosion resistance to acidic and alkaline solutions, excellent chemical stability, and does not participate in any chemical reaction during the smelting process. The inner wall of the graphite crucible is smooth, and the molten metal liquid is not easy to leak and adhere to the inner wall of the crucible, so that the metal liquid has good fluidity and castability, and is suitable for casting in various molds. Because graphite crucibles have the above excellent characteristics, they are widely used in alloy tool steel smelting and non-ferrous metal and its alloy smelting.

Graphite crucibles are mainly used for the melting of metal materials. They are divided into natural graphite and artificial graphite.

1) Natural graphite crucibles are made of natural flake graphite as the main raw material, clay and other refractory raw materials. They are generally called clay graphite crucibles, while those with asphalt as a binder are called carbon binder crucibles, and those made by the sintering force of clay alone are called microclay binder crucibles. The former is superior in strength and thermal shock resistance. It is used for the melting of steel, copper, copper alloys and other non-ferrous metals. Its size varies, and the melting capacity ranges from 250g to 500kg. This type of crucible includes accessories such as skimmers, lids, joint rings, crucible stands and stirring spoons.

2) Artificial graphite crucibles The above-mentioned natural graphite crucibles usually contain about 50% clay minerals, while the impurities (ash content) of artificial graphite crucibles are less than 1%. They are used for refining high-purity metals, and there are also high-purity graphites (ash content <20ppm) that have been specially purified. Artificial graphite crucibles are often used to melt small amounts of precious metals and high-purity metals or high-melting-point metals and oxides. It can also be used as a crucible for gas analysis in steel.