Product Overview/产品概述:

Calcium carbide, the product of calcium carbide furnace, has the molecular formula of CaC2 and the molecular weight of 64.10. The industrial product is gray, yellowish brown or black solid, and purple with a high content of calcium carbide. The newly broken surface of calcium carbide is shiny, and it loses its luster and becomes grayish white due to absorption of water when exposed to the air. The relative density is 2.22 (18℃). Industrial products generally contain 80% calcium carbide. The melting point is 2300℃. It can conduct electricity, and the higher the purity, the easier it is to conduct electricity. The chemical properties are very active and can react with many gases and solutions at appropriate temperatures. It decomposes violently in water to produce acetylene gas and calcium hydroxide, and releases a lot of heat. It can react violently with chlorine, hydrogen chloride, sulfur, phosphorus, ethanol, etc. at high temperatures.

Product Introduction/产品介绍:

Calcium carbide has many uses. It is an important basic raw material for the organic synthesis industry. Calcium carbide acetylene can be used as a raw material to produce ethylene, chloroprene rubber, calcium cyanamide, acetic acid, trichloroethylene, etc. Calcium carbide is also used as a desulfurizer for steel and is also used for metal cutting and welding.

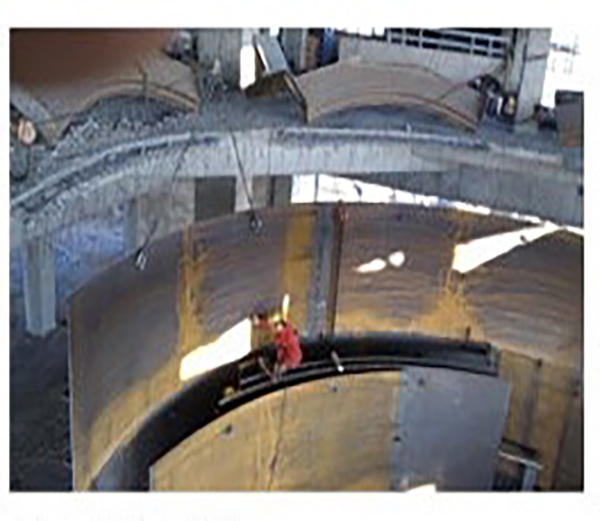

From the perspective of the development trend of submerged arc furnaces, closed submerged arc furnaces with low pollution, advanced process equipment, low energy consumption, safety and high efficiency will replace open submerged arc furnaces.

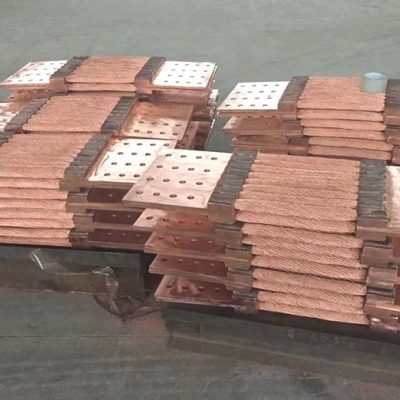

The combined holding system has the following advantages

1. It has strong applicability and can be used for submerged arc furnaces of different powers and different electrode diameters.

2. Compared with submerged arc furnaces using copper tiles as conductive elements, the contact resistance is better than other forms of contact resistance because the conductive elements and the electrode shell are compressed by springs and bolts, and there is no arcing, and the current transmission is stable.

3. Since the conductive elements adopt a closed design, the conductive elements are not radiated by high temperature, and their temperature rise is much lower than other forms of conductive elements, and the conductivity is significantly improved.

4. Due to the reduction of contact resistance, the improvement of conductivity, and internal water cooling, the electrical efficiency and power factor are significantly improved, energy saving is more than 5%, and material saving is about 20%.

5. Due to the reasonable structural design, the service life of the conductive elements is doubled. The daily maintenance cost is greatly reduced, and the equipment start-up rate is significantly improved.